With constant technology development and investment,

Kyungdong is proud of the best technical skill among domestic mines.

Safety System for Mines

It is impossible to overemphasize safety at mines

operated against enormous nature.

That is why Kyungdong designs the central intensive control center and

monitors the entire facilities of mines in real time and makes a full

preparation for safety management such as a remote operation system

for a winch/a battery locomotive car.

In preparation for emergency, special mine rescue training, which carries out actual training according to strict and systematic manual every half year, is a chosen background Kyungdong has been selected as a excellent mine for safety management by the government 9 times in total.

Safety Experience Hall

The existing two-dimensional frame of training was innovatively improved by operating the safety experience hall so that dangerous facilities and

critical accident situations that are difficult to experience directly can be directly and virtually experienced by combining the 4th industrial revolution

VR (Virtual Reality) technology with the field practice training.

| Classification | Type of Hands-on Facilities | How to Operate |

|---|---|---|

| VR Experience Hall |

1. VR Safety Experience

|

1. Subjects for Experience

|

| Dangerous Facility Experience Hall |

1. Dangerous Facility Experience

|

Composition of Safety Experience Hall

-

VR Experience

VR Experience

-

Dangerous Facilities Experience Center

Dangerous Facilities Experience Center

-

Impact on Safety Helmet

Impact on Safety Helmet

-

Finger Stricture Experience

Finger Stricture Experience

-

Electric Safety Experience

Electric Safety Experience

-

CPR/First-Aid Experience

CPR/First-Aid Experience

-

Serious Accident Case

Serious Accident Case

-

Dangerous Facility Experience

Dangerous Facility Experience

Gas, Collapse VR Experience Video

Special Rescue Crew

Special Rescue Squad

A rescue squad is organized with 21 professional skilled rescue crews in 4 squads equipped with special rescue equipment in order to do prompt and systematic rescue activities upon huge disasters such as gas explosion, water rushing out, fires or collapse etc. and we are equipped with the system available for a prompt response upon emergencies through regular trainings by external agencies and our own trainings for actual situations.

First-Aid Squad

Upon disasters in shaft, the unique field first-aid squad in domestic mines is organized with 30 workers in 6 squads to secure golden time before the special rescue squad arrives at the spot and we are equipped with a perfect system to secure golden time through regular trainings for actual situations and operation and proficiency of special rescue equipment.

Rescue Workers

Upon emergencies at the working sites in shaft, 24 workers at the working sites are selected and utilized as rescue workers at sites in shaft through professional trainings for first aid by the Republic of Korea National Red Cross and repetitive trainings by our own professional first aid instructor.

Photos of Trainings of Special Rescue Squad

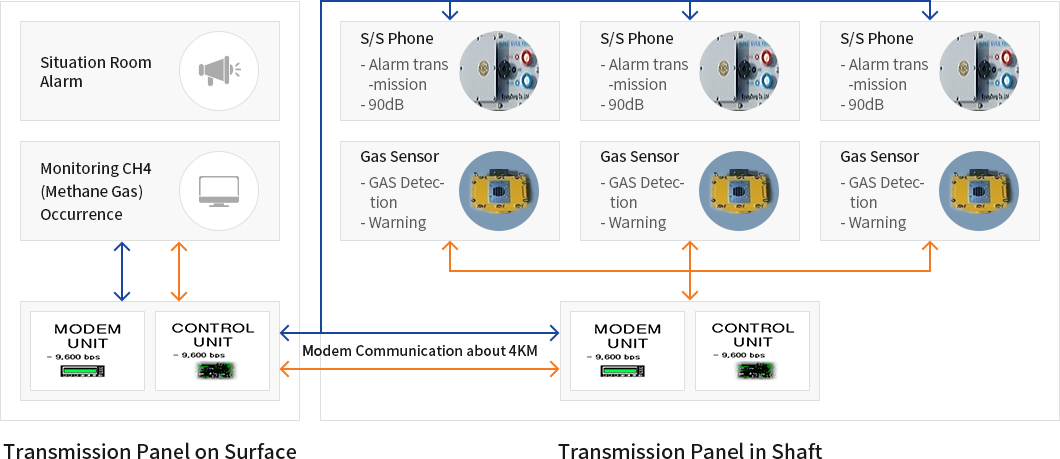

Methane Gas Monitoring

Purpose

It is aimed at preventing gas disaster through a prompt emergency response upon detecting methane gas in shaft.

Status of Operation

- A stationary gas detector is installed at coal mining sites and preparation sites for production in shaft and we are equipped with a system that when gas is detected in linkage with the central intensive control center, an automatic warning alarm is sent to the control center and working sites by S/S phone simultaneously and it is possible for prompt responsive actions by step.

- Besides, it is possible to check the status of real-time occurrence at a personal computer by linking the data on gas detection with the ERP system and we are preemptively responding to prevention of gas disaster by analyzing tendency of gas generation through management of the accumulated data.

Block Diagram of Methane Gas Monitoring System

Detecting more than 1% methane gas

Transmitting automatic alarm and an announcement simultaneously by S/S phone to the control center and working sites

⇒ Person in charge : C/C forceful stop of working sites and notifying gas generation by S/S phone

Detecting more than 2% methane gas

Transmitting automatic siren and announcement for evacuation simultaneously by S/S phone to the control center and

working sites

⇒ Person in charge : Announcement by S/S phone to notify gas generation and evacuation

Video Showing Methane Gas Response System

Upon methane gas, a response system at working sites

Mine Safety Equipment

Respirator (BG174)

- Usage : Equipment for respiration worn by mine special rescue crews upon special rescue activities in shaft (gas, fire etc.)

- Time of Use : 4 hours and 30 minutes (upon 200 air pressure charged)

Gas Detector

A stationary gas detector (KDM 5.0G)

- It is installed at places that are expected to generate methane gas such as coal mining sites and preparation sites for production etc. and linked with

the central intensive control center by communication and the monitoring system is maintained all the time. - Range of Detection : CH4 GAS 0.1% ~ 4.7%

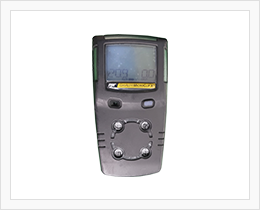

A portable digital gas detector (Micro Clip)

- It is a digital gas detector that can be carried by an individual and detect gas automatically and safe works are promoted by giving it to workers of coal

mining, digging and shaft supports. - Range of Detection : CH4 GAS 0.1% ~ 5.0%

A portable analog gas detector (R7)

- It is an analog gas detector that can be carried by an individual and directly measure gas and is operated for supplementing a digital detector at

sections with a large quantity of gas. - Range of Detection : CH4 GAS 0.1% ~ 10%

Rescue Equipment

Self-service respirator (A mask generating oxygen for evacuation from a fire)

Self-service respirator is a one of important equipment as a quick escape from the scene of an accident in the event of a fire in the mine, the entire workshop and restaurant in the mine are prepared for the number of mine workers. All employees are fully trained through regular training.

AED(NF1200)

Upon emergencies such as a patient with cardiac arrest etc. in shaft, AED is prepared at each cafeteria in shaft so that a prompt action can be taken and it is ensured that a prompt use is available by conducting a regular practice training for all employees.

SCBA

Upon a patient with difficulties in breathing in shaft, a portable oxygen tank is prepared at each cafeteria in shaft so that a prompt action can be taken and it is ensured that a prompt use is available by conducting a regular practice training for all employees.

-

Respirator

Respirator

-

Stationary Detector

Stationary Detector

-

Micro-clip Detector

Micro-clip Detector

-

AED

AED

-

R7 Detector

R7 Detector

-

Self-Service Respirator

Self-Service Respirator

-

SCBA

SCBA