With constant technology development and investment,

Kyungdong is proud of the best technical skill among domestic mines.

New Technology of Kyungdong

Remote Operation of Mine hoist

Overview

Kyungdong developed the first remote operation of a winch device surpassing the level of developed countries and has installed it at 2 places since July of 2007 and started operation and completed test operations until October successfully and is currently in process of remote operation of a winch device at 7 places. This is a splendid achievement thanks to fostering human resources and creativity of technology innovation that have been progressed as part of the management policies of the company and it is a milestone for advancement of technologies, cost saving and disaster prevention at industrial sites, which is surely a pride of Kyungdong. We will build an automation system of the entire mechanical devices and equipment in the company for improvement of efficiency and disaster prevention in the future.

Understanding on Unmanned Operation of Mine hoist Device

- It is intended to receive signals of a remote controller by installing a control panel for remote operation at the existing control panel of a winch additionally so that the winch can be operated and controlled.

- A remote controller of a winch is downsized and it is intended to be operated as a person aboard wishes by operating it manually with putting it on a shoulder.

- A monitor at each roller helps a person aboard upon operation and a separate monitoring device is installed at the central intensive control center so that whether a winch operates normally or not can be monitored all the time.

Effects

Upon operating a winch, it is operated through mutual communication between an operator and a person aboard but it became possible for remote operation of a winch through development of a remote operation device so one person aboard can adjust the speed of a winch and the position of a stop freely, which creates an effect of saving personnel and improving productivity and safety.

- Saving personnel since only one person aboard operates a winch for transport works

- Quick response to safety accidents upon emergencies since a person aboard directly operates a winch

- Safe transport works since it is possible for a person aboard directly to adjust the speed upon transporting main materials and heavy objects

Remote Operation of Battery Locomotive Car

Purpose

A battery locomotive car has been operated by a group of two persons an operator and an assistant but it creates effects of saving personnel and improving productivity and preventing disaster since it is possible for remote operation through development of a remote control device for a battery locomotive car and one operator can adjust the speed and the position of a stop freely.

Effects

- Saving personnel since one operator operates a battery locomotive car

- Preventing disaster since one operator directly checks and operates a battery locomotive car

- Preventing disaster since one operator operates the mining car by pins while operating it directly

- Contributing to improvement of productivity with quicker transport by operating a rail point directly since distance of communication of the remote control device is about 40m

- Preventing disaster of transport works since an assistant jumps on and off for operation of the rail point

- Safe transport works for main materials and heavy objects since an operator of a battery locomotive car can adjust the speed freely

Central Intensive Control Center

Purpose of Operation

It is aimed at maximizing efficiency by saving energy and extension of life of equipment through prevention of disaster and efficient operation of equipment such as saving personnel etc. by monitoring all mechanical and electric facilities that are installed in shaft and on surface intensively and operating them remotely.

Status of Central Intensive Monitoring and Control Facilities

Chain Conveyor

It is the equipment that transports coal produced from the coal mining site to the place of stocking hutches and monitors idle operation and overload operation of machine and has an effect of reducing waste of power upon idle operation and abrasion rate of machine and solves problems such as abrasion and damage of motors due to overload operation.

Belt Conveyor

It is the facility that transports coal and pumice stone produced in shaft to the surface and is equipped with the system that can promptly recognize the broken part and its location etc. through a monitor and respond to it quickly.

CH4 Gas Sensor

It is installed at the place of producing CH4 gas at each coal mining site and the preparation site for the real-time monitoring and it has a great effect of preventing gas disaster by stopping operating equipment and alerting workers to escape automatically through S/S phone at the working site in shaft when CH4 gas is generated more than the standard value.

Local Fan

It is the facility that secures quantity of local airflow of each working site and has an effect of improving environment of working sites and safe works as well as saving energy by remote operation.

Transformation Facility

It receives and transforms the electricity of 154KV and supplies and controls it remotely up to a working site using the power and it has an effect of saving energy and preventing disaster of an electric shock by controlling and operating the quantity of using electricity systematically.

Transformer in Shaft

It is the facility that supplies the power to each facility installed at working sites in shaft and has an effect of saving energy and preventing a fire due to overheating through a remote stop.

Main Drain Pump in Shaft

Pumps installed at each place in shaft and on surface are operated remotely and equipment is controlled efficiently by monitoring the situation of fields with a monitor in real time through automatic water level adjustment.

Air Compressor

It is a mechanical facility that supplies compressed air required for each working site and it prevents disaster, saves personnel and checks whether it is normal or not by monitoring data on every sort of failure by remote operation.

Boiler, Washing Waste Water Treatment Facility

It actualizes prevention of disaster, saving personnel and efficient operation of equipment by unmanned remote control at the control center.

Modernization of Mining Equipment

Coal Mining Equipment

Super Coal Miner

It is an excavator that is used for loading coal onto the chain conveyor, half-coal, constructing supports and lifting heavy objects etc. at the coal mining sites and it has an explosion-proof structure and its boom can rotate 180 degree so it is possible to work on the side wall in a narrow section and it has a great effect of lowering dependency on personnel and improving productivity and saving costs and preventing disaster.

Long Hole Auger Drill

It is a pneumatic auger drill and is mainly used for upward drilling for a long hole blasting at coal mining sites and is sometimes for horizontal drilling when checking the width of blasting and water bags.

Digging Equipment

Side Dump Loader

It is the equipment that loads pumice stone produced upon digging works onto a hutch by side dumping, and is sometimes used for auxiliary works of constructing supports (transport, unloading etc.

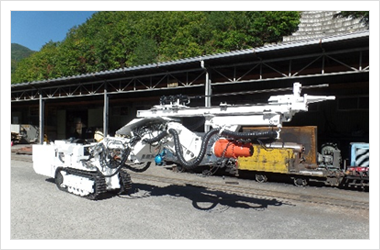

Pneumatic 2-Boom Drill

It is the equipment that is used for drilling upon digging and uses 2 booms and a pneumatic rock drill and the lower crawler is made by self-production using S.D.L, and it is available only when the cross section should be at least 3.8mx2.8m to use the equipment.

Hydraulic Drilling

The equipment (Hydraulic Drilling / The same body as S.D.L equipment is applied) for two purposes of dealing with pumice stone and drilling is made by making a detachable drill unit and bucket for S.D.L (Side Dump Loader) which is exclusively used for dealing with pumice stone previously.

Transportation Equipment

Explosion-Proof Battery Locomotive Car

It is the transport equipment that is used for bituminous coal and pumice stone and materials and an explosion-proof type and there are 3-ton, 5-ton and 8-ton battery locomotive cars.

Belt Conveyor

It is a scraper assembled into a sigma type frame with a link chain and a shackle and it is machine trasporting things and used for transporting raw coal of the coal mining.

Chain Conveyor

It is machine that loads things onto a belt which operates in a circular shape and transports them continuously and is widely used as machine transporting coal and pumice stone in shaft and on surface.